From Engineering to Production — Complete In-House Solutions

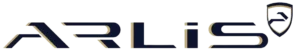

Product Development – From Concept to Reality

Product development starts with understanding your idea and turning it into a functional, manufacturable solution.

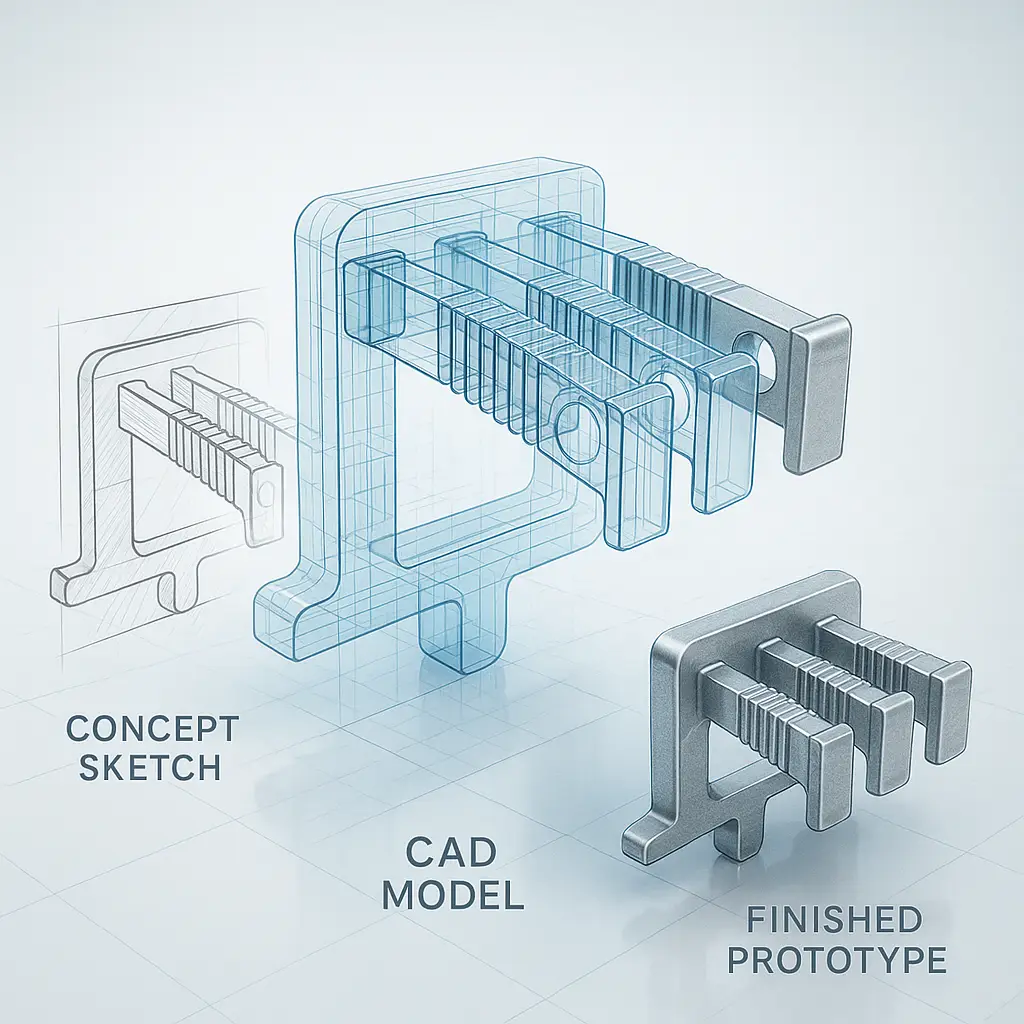

Our engineers combine technical expertise, advanced 3D modeling, and simulation tools to design products optimized for performance, reliability, and cost efficiency.

We work closely with our clients through all stages — from early sketches and feasibility analysis to prototyping and testing.

By validating mechanical properties and production feasibility early on, we minimize risks and accelerate your time-to-market.

🔹 Our capabilities include:

3D modeling and design optimization

Rapid prototyping and functional testing

Design for manufacturing (DFM) and cost analysis

Product visualization and presentation renders

Every project is treated individually, ensuring that the final product not only looks great but performs flawlessly in real-world conditions.

Die Casting – Strength and Precision Combined

With over 20 years of experience in high-pressure die casting, Arlis d.o.o. specializes in precision Zamak components for a wide range of industries.

Our company operates wth 7 modern die-casting machines from Frech, Agrati, and Colosio, with clamping force range 50 to 140 tons. Delivering reliable, high-efficiency production of complex and dimensionally precise parts.

We serve various sectors including the furniture, household appliance, automotive, and other industries.

🔹 Our key advantages:

Stable and repeatable casting quality

Precise temperature and process control

Optimized tooling and cooling systems

Every casting reflects our commitment to precision, durability, and consistency — from the first to the last piece .

Automation and Machine Engineering – Smarter Production

Automation is the key to efficiency and consistency.

We design and build custom machines tailored to your production needs — from component assembly to testing and packaging.

Each system is developed in-house, integrating mechanical, pneumatic, and electronic control systems.

Because we build our own machines, we can adapt them perfectly to your products and optimize every process step.

🔹 We specialize in:

Automated assembly systems

Thread forming and screw insertion units

Testing, measurement, and quality inspection stations

Fully integrated production lines

Our automation solutions save time, reduce human error, and provide a repeatable, efficient workflow — ready for continuous operation in industrial environments.

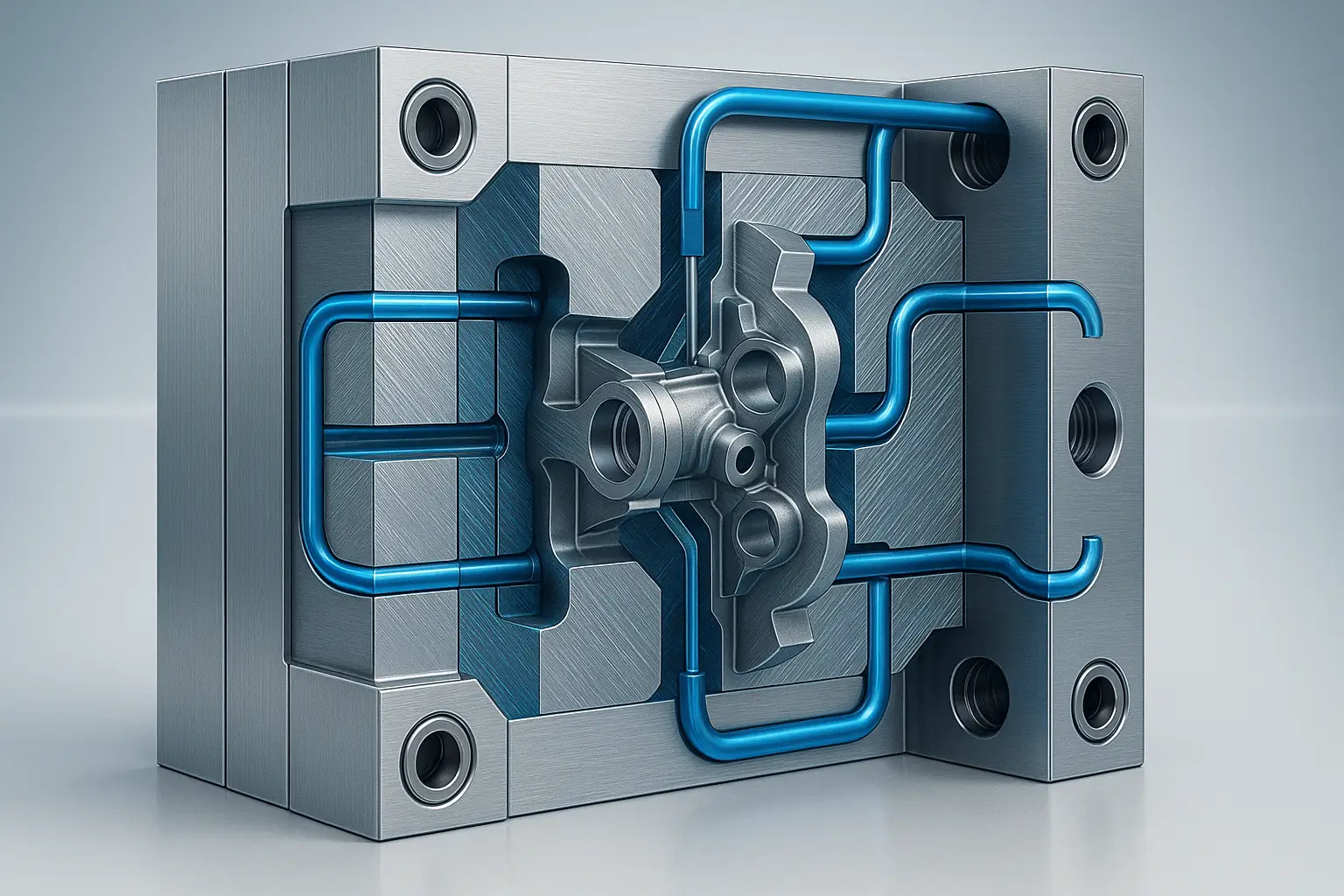

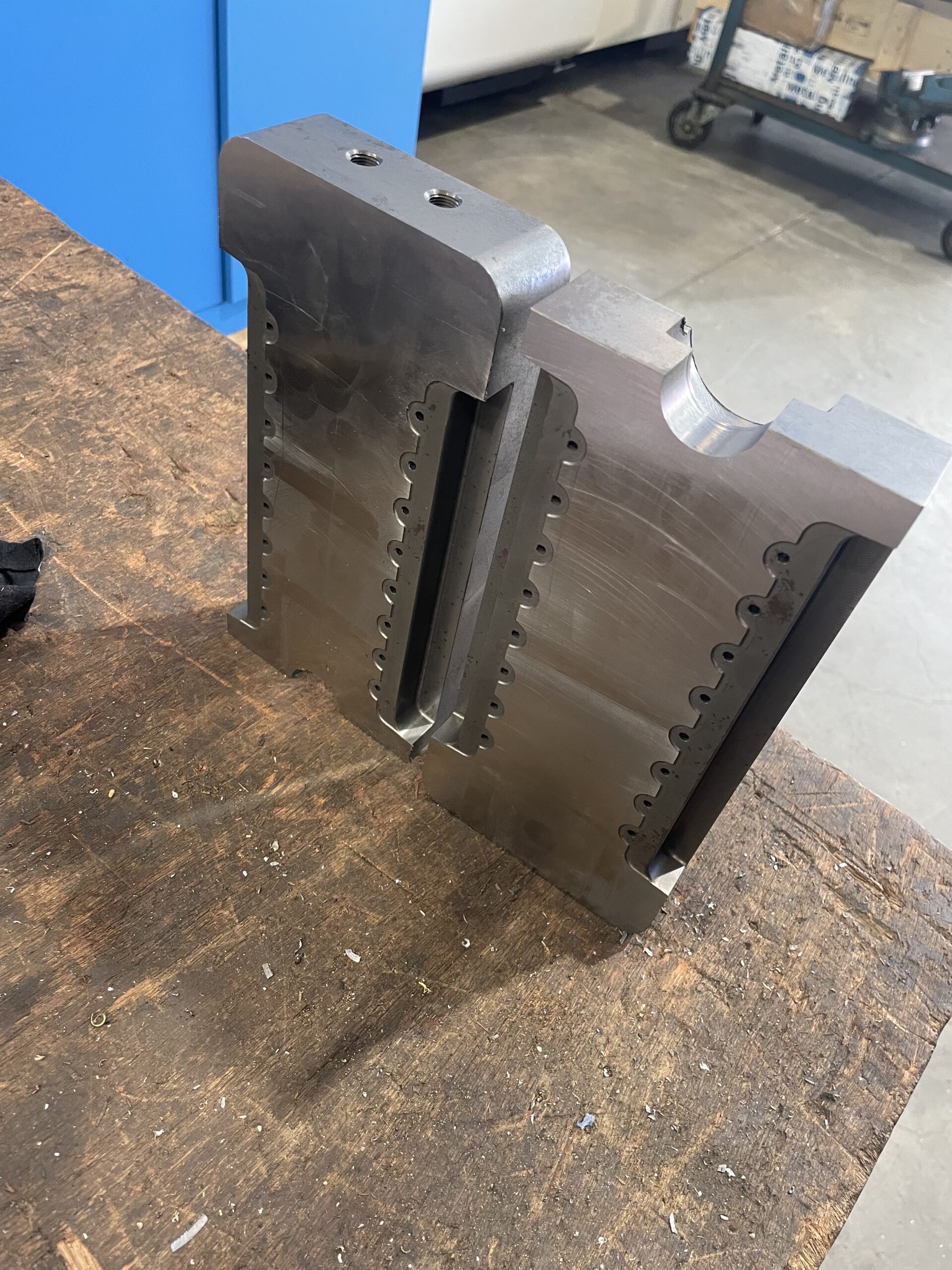

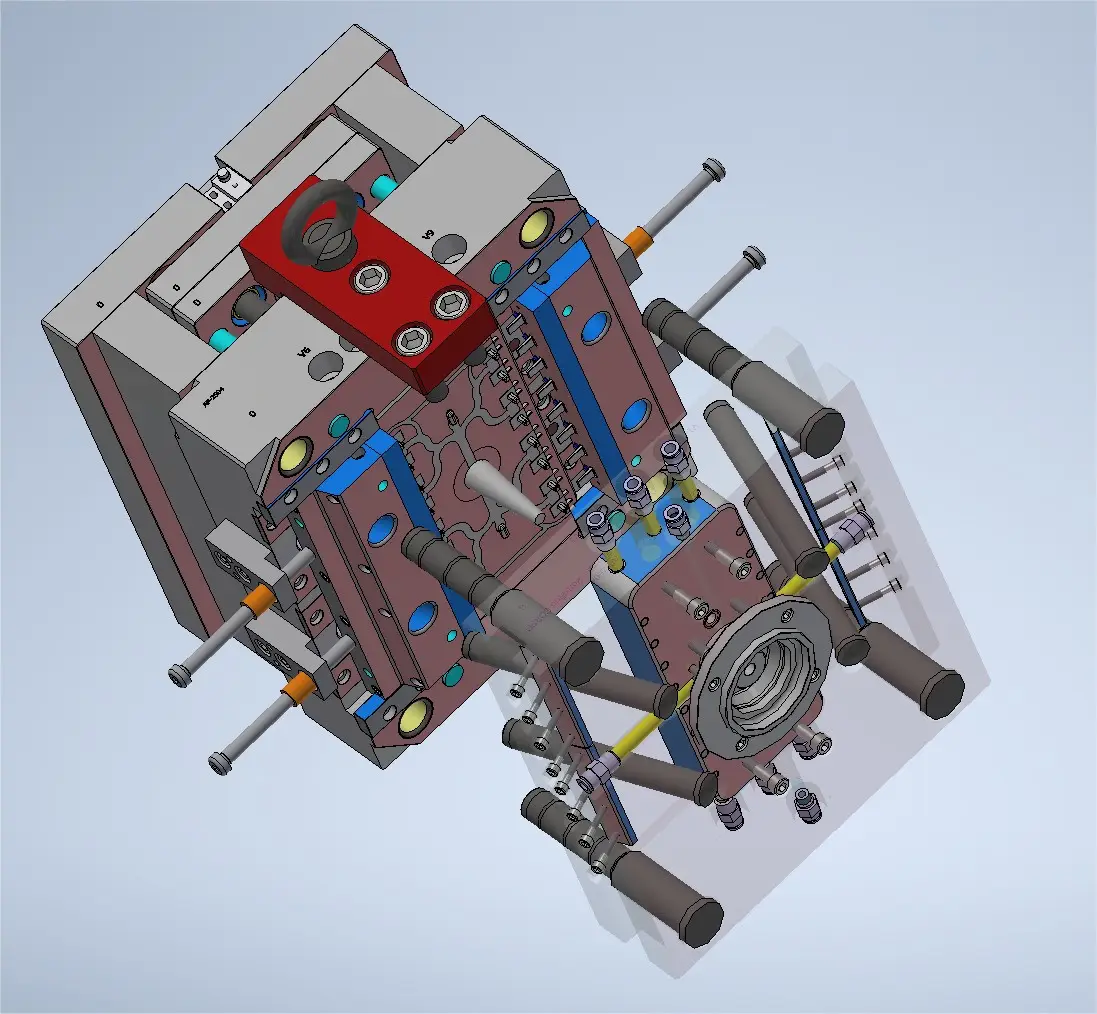

Toolmaking – Advanced Engineering for Every Mold

Our in-house tool shop designs and manufactures high-quality molds for plastic injection and die casting of aluminum and zinc alloys.

Each tool is engineered to ensure longevity, efficient cooling, and easy maintenance — with precision measured in microns.

Using modern CNC machining centers like OKUMA, MAKINO, YASDA and EDM technology SODICK, we achieve exceptional accuracy and repeatability.

Our experience in tooling allows us to predict production behavior and optimize cycle times even before the first test shot.

🔹 Tooling services include:

Mold design and simulation

High-precision machining and EDM

Assembly and test runs

Maintenance, modification, and optimization

We ensure every tool is ready for long-term, high-volume production — built to deliver consistent performance, cycle after cycle.

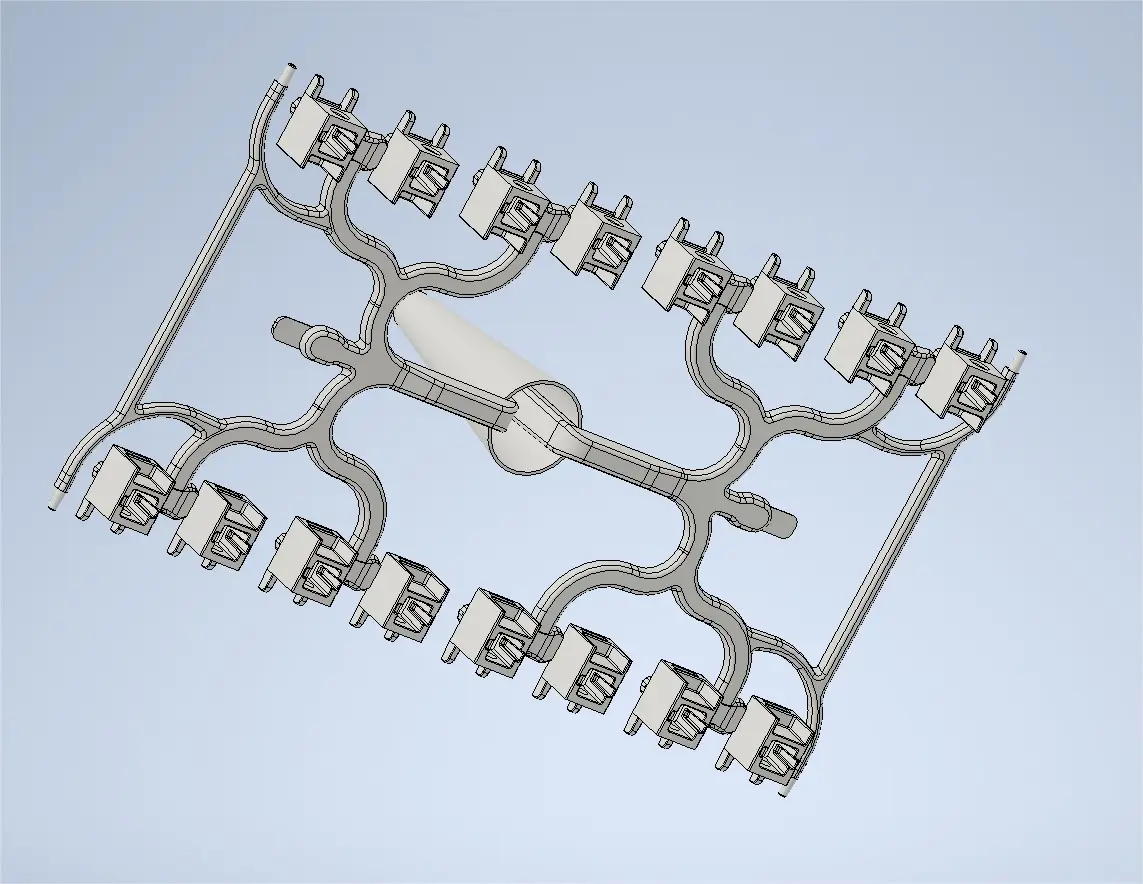

Reliable Plastic Injection Molding

Our high-quality plastic injection production features 7 modern all-electric Krauss Maffei machines with clamping forces ranging from 80 to 160 tons.

Our technology ensures maximum precision, energy efficiency, and repeatable quality throughout the entire production process.

We produce technical and aesthetic components for the furniture, household appliance, automotive, and other industries, using materials such as PP, PA6, ABS, and others.

Assembly, Testing, and Packaging – Complete Product Solutions

We provide full post-production services — from assembly and testing to professional packaging and warehousing.

Our modular workstations support manual, semi-automatic, and fully automated assembly, ensuring flexibility for different product types and batch sizes.

Every product is checked for mechanical accuracy, assembly precision, and functional performance before packaging.

We use protective materials and standardized labeling for traceability and safe delivery to customers worldwide.

🔹 Our post-production services include:

Assembly of multi-component products

Functional and quality testing

Packaging and labeling according to industry standards

Short- and long-term warehousing solutions

With complete control over every step, we guarantee that each finished product meets the highest standards of quality and reliability.

We don’t just produce components — we deliver complete, production-ready solutions that bring your ideas to life.

WHEN, if not NOW?